Dual head, no maintenance, hi-resolution alternative to continuous inkjet coder

Print up to 25mm in height, and up to 180m/min.

Gone are the days when printing meant constant troubleshooting and messy ink spills. With the revolutionary TIJ inkjet coder (Thermal Inkjet Printer), your printing woes will disappear faster than ink drying on paper! The TIJ inkjet coder, also known as the Thermal Inkjet Printer, has taken the industrial printing market by storm. Its advanced technology and user-friendly features make it the go-to choice for businesses worldwide.

Incredible Value, Unprecedented Performance of RNJet H2+ Thermal Inkjet printer

ONE OF THE HIGHEST SPEEDS ON THE MARKET for TIJ PRINTERS

Print speeds for dynamic data can reach up to 180m/m at 150 dpi

FREE-MAINTENANCE CODER

This printer requires 0-maintenance, keeping your line moving smoothly

VARIETY OF INK COLORS

Ink available in a variety of colors (black, red, blue, green, pigmented white, pigmented yellow, FDG blue and FDG pink), including UV black and white

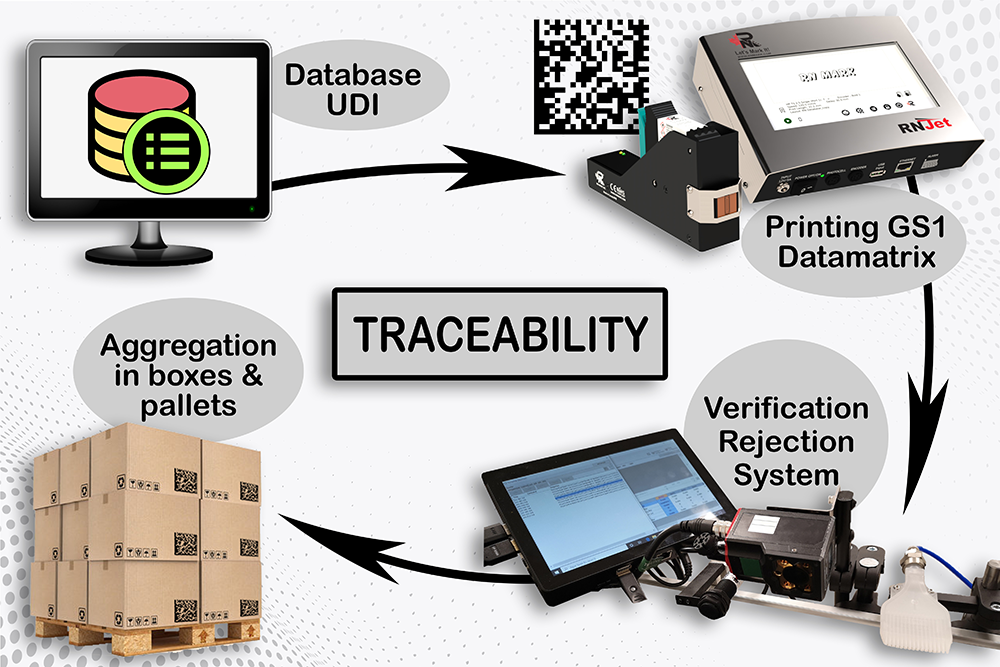

DATABASE PRINTING

Printing a variable data, unique information from database, GS1 Data Matrix & UDI, Track and Trace, any type of codes, ability to print from PLC and NiceLabel

Specifications of Inkjet Coding Printer RNJet H2+

Max. Height

Print up to 25mm in height using 2 heads, or up to 12.7mm with each head individually.

Drying Time

Ink dries in 1-3 seconds on non-porous materials.

Print Speed

Print up to 180m/min at 150 dpi, or 90m/min at 300 dpi.

Storage

Internal memory can store 1000+ unique messages.

Print Resolution

Print at up to 300 dpi, depending on line speed.

Throw Distance

Print head can be placed up to 8mm away from the object.

Printing Ink

A variety of solvent and water based inks are available in red, blue, black, pigmented white and yellow, as well as UV black and white. Includes low ink alarm and consumption calculator.

Controller

Our reliable 7″ LCD controller is durable, dust resistant, and has fast communications. Upload any font, image, or design you want with ease.

Canadian Quality

We are a proudly Canadian company; our machines are designed and fully manufactured by our skilled team of technicians in Ontario

Print Head

Dual Thermal HP TIJ 2.5 print head system. Allows 2 heads to run on the same production line, printing different information on different sides.

Expiry Date Coder RNJet H2+ is an ideal for small character coding on different applications, such as:

- PVC pipes

- Extrusions

- Cables and wires

- Egg cartons

- Electronic components

- Glass bottles and containers

- Plastic bottles and containers

- Rubber parts

- Tins and cans

- Metal components

- Flexible plastic films

- Shrink wraps

- Woods

- Epoxy laminate and PCB boards

- Molded plastics

- Cardboard and recycle papery

- Corrugated boxes

- PPE, sanitizers and masks

- and more!

RNSoft for RNJET Industrial inkjet printers

Each inkjet coder comes pre-loaded with our Windows based software, free of charge. This user-friendly software is capable of printing the following data on practically any surface you need:

- Static text

- Auto date & time

- Julian date

- Jalali date

- Auto manufacture date

- Auto expiry date

- Batch number

- Serial number

- Auto shift codes

- Logo

- Image

- QR code

- GS1 Data Matrix

- UDI

- Database

- Counter

- External text (weight & other info from scale and barcode scanner)

Our specialized Windows-based software comes equipped with a low ink indicator and ink level calculator. When the ink cartridge is inserted, RNSoft measures the remaining ink level and lets you know when it’s time to replace , so you can closely monitor each individual color and cartridge, never missing a print.

With RNSoft, handling any marking requirements, big or small, is easy. The software allows up to 100 injet coders to be connected to one PC simultaneously.

More Coding and Marking Solution

Explore the possibilities of A+++ Industrial inkjet coders…

Inkjet Coder RNJet H1+

Doesn’t need any attention, because it just keeps going!

TIJ Printer, Maintenance free

Industrial Inkjet Printer RNJet E1-72+

Serious Performance for Serious Requirements.

Single head, large character

Batch Coder RNJet 100

Incredible Value, Unprecedented Performance!

Single head, more advanced inkjet coder

Optional Vision Inspection Solutions for Marking & Coding Quality

We are proud to offer full-featured, powerful vision systems which perform fast, accurate inspections of every product marking that passes through your production line.

These thermal industrial printers help to ensure quality and compliance by checking the print quality, position, readability and accuracy of codes.

This works by obtaining serial number information from the company or manufacturing server. Each object is marked with an encoded, unique serial number using a Data Matrix. A sophisticated vision system consisting of multiple cameras verifies the quality of the markings, and an integrated reject system reliably removes failed items from the production line.

Our knowledgeable team would be happy to provide more information about our powerful visual inspection systems, and how they can help strengthen your production line!