Friction Feeder Solution

A friction feeder, also known as a paging feeder or carton feeder, is a high-performance device designed to separate and feed individual items—such as paper sheets, cartons, cards, or bags—onto a conveyor or into a processing machine. This versatile machine plays a crucial role in packaging lines, printing setups, labeling operations, and fulfillment processes where accuracy, speed, and flexibility are essential. Whether you’re feeding product inserts, marketing flyers, blister cards, cartons, or packaging bags, a friction feeder ensures smooth, continuous, and reliable feeding to keep production flowing efficiently.

Friction Feeder Solution with Industrial Printer

HIGH SPEED FEEDING

With speeds up to 30 meters per minute and adjustable RPM control (90–1350 RPM), this feeder keeps up with demanding production lines.

COMPACT AND DURABLE

Built from 201 stainless steel, it’s corrosion-resistant and ideal for industrial use. Its compact footprint allows easy integration into existing setups.

EASE OF INTEGRATION

This feeder can be combined with labelers, printers, and packaging machines, serving as a core component in automated production systems.

VERSATILE MATERIAL HANDLING

It can handle a wide variety of items—flat, thin, or rigid—making it a multi-use solution for different packaging and printing needs.

Get a Free Quote

How to Select the Right Friction Feeder

Friction feeders are commonly found in many industries due to their flexibility and reliability:

✔ Product Material

Are you working with paper, plastic, foil, or cartons? Some materials may need specialized friction belts.

✔ Product Size & Thickness

Ensure the feeder’s adjustable width and thickness range match your product dimensions. This model supports items from 0.1 mm to 6 mm thick and up to 11 inches wide.

✔ Feeding Speed Requirements

If your production line runs fast, opt for a feeder with a high-speed capability like 30m/min.

✔ Integration Needs

Decide whether the feeder will be standalone or integrated into a larger system with sensors, coders, or labelers.

More Coding and Marking Solution

Explore the possibilities of A+++ Industrial inkjet coders…

Inkjet Coder RNJet H1

Doesn’t need any attention, because it just keeps going!

TIJ Printer, Maintenance free

Industrial Inkjet Printer RNJet E1-72+

Serious Performance for Serious Requirements.

Single head, large character

Batch Coder RNJet 100

Incredible Value, Unprecedented Performance!

Single head, more advanced inkjet coder

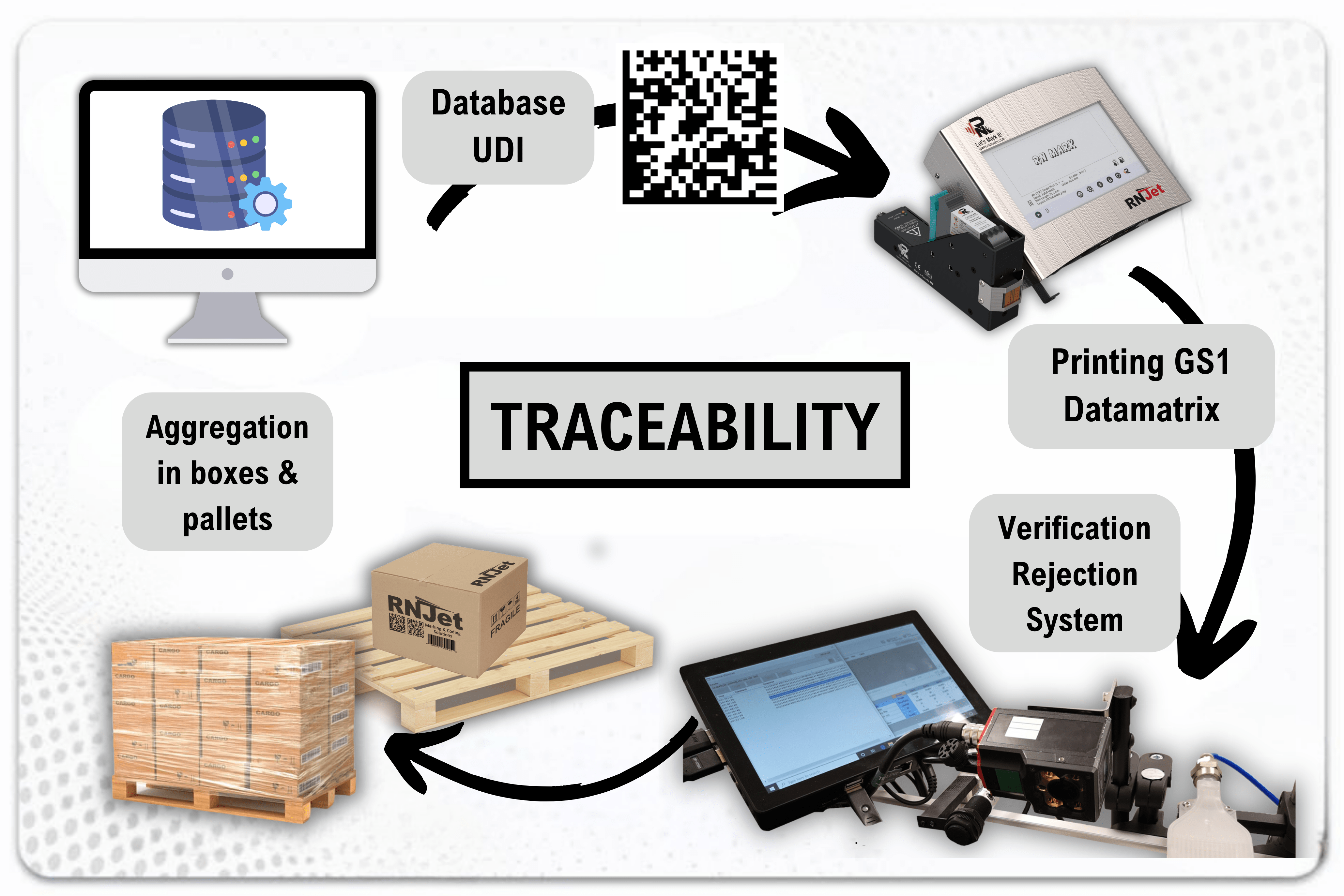

Optional Vision Inspection Solutions for Marking & Coding Quality

We are proud to offer full-featured, powerful vision systems which perform fast, accurate inspections of every product marking that passes through your production line.

These thermal industrial printers help to ensure quality and compliance by checking the print quality, position, readability and accuracy of codes.

This works by obtaining serial number information from the company or manufacturing server. Each object is marked with an encoded, unique serial number using a Data Matrix. A sophisticated vision system consisting of multiple cameras verifies the quality of the markings, and an integrated reject system reliably removes failed items from the production line.

Our knowledgeable team would be happy to provide more information about our powerful visual inspection systems, and how they can help strengthen your production line!