In the competitive bakery industry, product presentation and traceability are crucial. RNJet coding and marking solutions provide high-quality printing for bakery products like plastic boxes, containers, cardboard box or any products to stand out while maintaining compliance and traceability.

RNJet Industrial Inkjet Printer

Baked Goods Coding and Labeling Solutions

Investing in RNJet coding and marking solutions means choosing reliability, efficiency, and quality. Our printers are designed to meet the unique needs of the bakery industry, providing robust and versatile solutions for all your packaging needs.

Incredible Value, Unprecedented Performance of RNJet H1 Thermal Inkjet printer

ONE OF THE HIGHEST SPEEDS ON THE MARKET for TIJ PRINTERS

Print speeds for dynamic data can reach up to 180m/m at 150 dpi

FREE-MAINTENANCE CODER

This printer requires 0-maintenance, keeping your line moving smoothly

VARIETY OF INK COLORS

Ink available in a variety of colors (black, red, blue, green, pigmented white, pigmented yellow, FDG blue and FDG pink), including UV black and white

DATABASE PRINTING

Printing a variable data, unique information from database, GS1 Data Matrix & UDI, Track and Trace, any type of codes, ability to print from PLC and NiceLabel

Why Reliable Marking is Essential for Bakery Packaging

1. Brand Identity

Clear, high-quality printing enhances your brand’s visibility and attractiveness on store shelves. RNJet printers allow for the seamless addition of logos, product names, and intricate designs, ensuring your packaging is both eye-catching and informative.

2. Regulatory Compliance

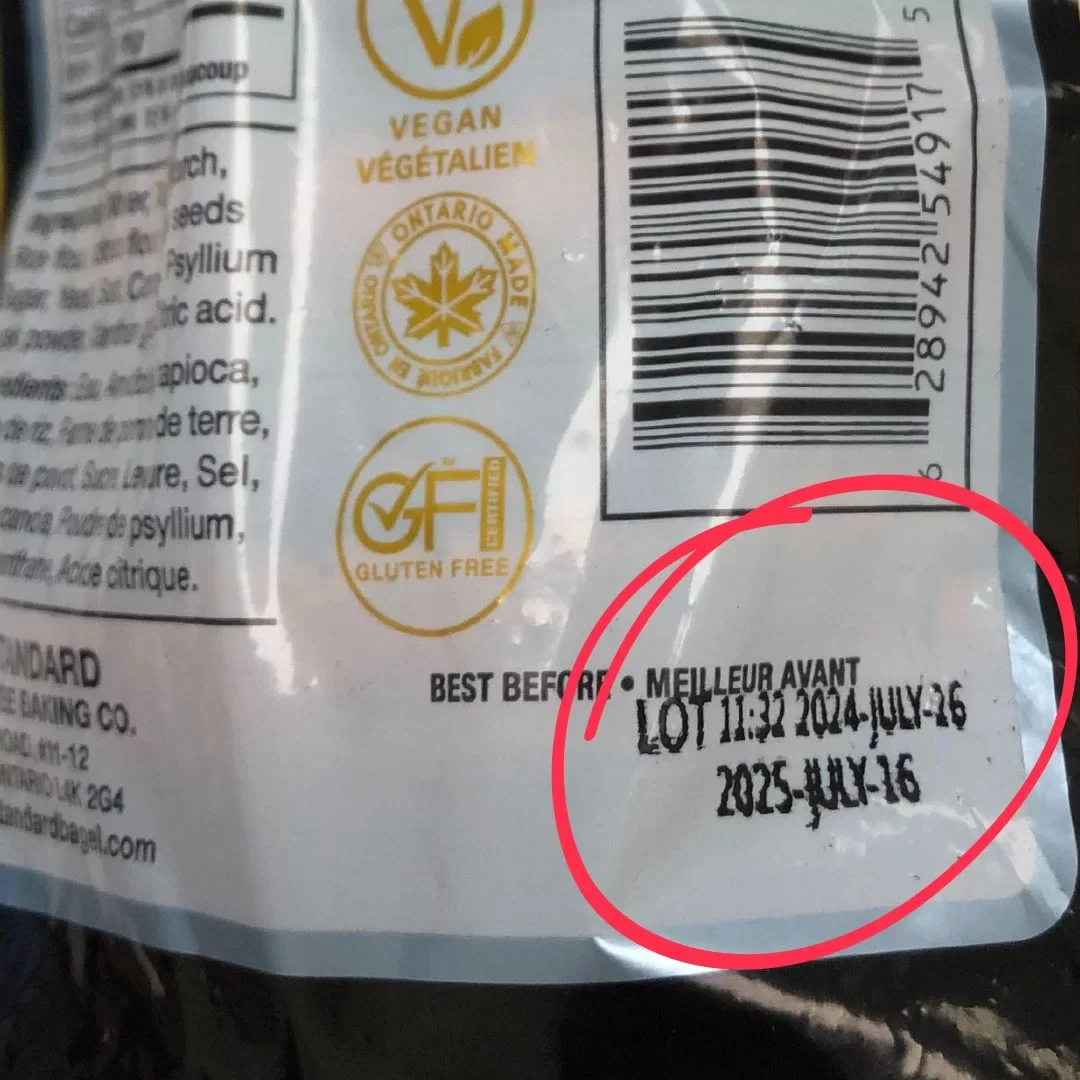

Food products, including bakery items, must comply with local and international regulations. Reliable marking ensures that all necessary information, such as ingredients, allergens, expiration dates, and nutritional facts, is accurately displayed. This helps avoid legal issues and keeps the bakery in compliance with food safety laws.

3. Product Traceability

Accurate markings such as batch numbers, production dates, and expiry dates are critical for product traceability. In case of a recall, this information helps quickly identify and isolate affected batches. It’s also essential for maintaining transparency and consumer trust.

4. Customer Safety

Proper labeling helps to highlight important safety information, such as allergens or instructions for storage and handling. Reliable marking reduces the risk of consumers unknowingly consuming ingredients that could harm them, especially in cases of food sensitivities.

Printing on Bread Bags

Printing on bread bags is essential for providing clear, legible labeling that ensures consumers can easily access important product information such as ingredient lists, nutritional facts, and expiration dates. Additionally, printing on bread bags enhances brand visibility, as it allows bakeries to incorporate their logos and designs on the packaging. With advancements in printing technology, bakeries can now print directly on bread bags with high-resolution images, ensuring both quality and compliance. The use of quality inks and printing methods also ensures that the text remains readable even when the bag is exposed to moisture or handling, keeping the product’s information intact throughout its shelf life.

Printing on Plastic Packaging

Printing on bags, whether for bulk ingredients, bakery products, or other food items, is crucial for maintaining product integrity and meeting regulatory requirements. Bags are a common form of packaging because they are versatile and cost-effective, and they offer ample space for labeling. Printing on bags helps companies include essential information such as production and expiration dates, ingredients, weight, and safety warnings. By investing in high-quality printing solutions, businesses can ensure that the printed information remains clear and durable throughout the product’s journey. Furthermore, using eco-friendly or recyclable bags and employing sustainable printing methods aligns with growing consumer demand for environmentally responsible products.

Printing on Flow Pack

Printing on flow pack packaging is increasingly popular in the food industry, especially for products like snacks, bakery items, and confections. Flow packs are commonly used for their durability and ability to preserve product freshness. With the ability to print directly on the film material, manufacturers can apply product information such as batch codes, expiration dates, and branding. This type of printing also enables efficient automation, reducing manual labor and increasing throughput on high-speed production lines. By integrating printing directly into the flow pack process, companies can ensure consistent and accurate labeling while enhancing their product’s appearance, ensuring customer trust and compliance with food safety standards.

Printing on Cartons

Carton packaging plays a critical role in protecting bulk food items during storage and transportation. Printing on cartons not only serves as an identifier but also provides valuable information like product details, shipping instructions, and handling warnings. Additionally, printing directly on cartons allows for easy identification during inventory management and distribution. The use of high-quality printers ensures that the printed information remains intact and legible even after the carton has been stacked, moved, or exposed to environmental factors. This is particularly important for businesses looking to improve the accuracy of their logistics, reduce the chance of errors during shipment, and ensure that products are delivered in top condition.

More Coding and Marking Solution

Explore the possibilities of A+++ Industrial inkjet printers…

TIJ Coder RNJet T1

Doesn’t need any attention, because it just keeps going!

TIJ Printer, Maintenance free

Industrial Inkjet Printer RNJet E1-72+

Serious Performance for Serious Requirements.

Single head, large character

Batch Coder RNJet 100

Incredible Value, Unprecedented Performance!

Single head, more advanced date, batch & lot coding machine