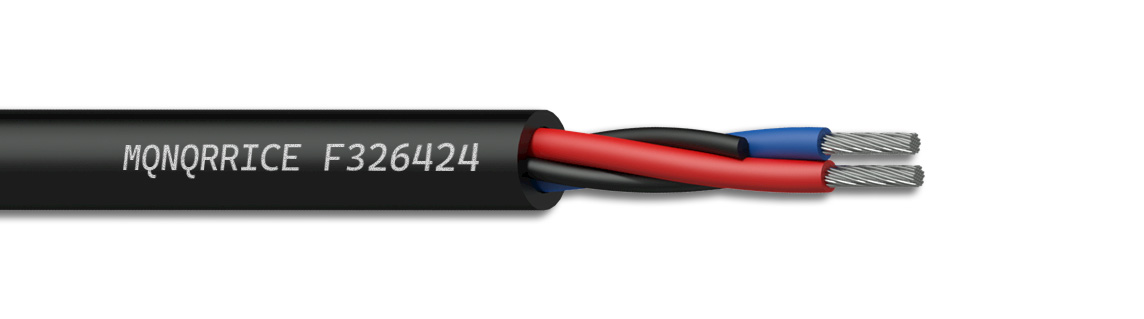

In the dynamic cable industry, high-precision and quality printing are essential for various cable types. RNJet coding and marking printers excel in providing rapid printing speeds and fast-drying inks, suitable for all types of cables. Our printers deliver top-notch code printing across all cable sizes with quick changeovers, ensuring low ownership and operational costs.

Coding and Marking Solution for Wire and Cable

For wire and cable manufacturers, running production lines at full capacity is critical for profitability. Even minor issues can have significant impacts in high-speed environments, causing downtime or generating scrap. Our TIJ printers are designed to endure tough conditions, seamlessly integrate into workflows, and meet demanding production requirements. Discover our range of wire and cable marking technologies and their specifications below.

Hi-Resolution Coder RNJet 100

Print on Cable and Wire with RNJet 100

RNJet 100 is the perfect choice for you if:

- The print’s 18 mm height is sufficient for your needs

- Economical cost of printing is your target

- Hi-resolution printing on porous or non-porous material is needed

- Any angle (even upwards!) printing is required

Databases printing I UDI I LOGO I Barcodes I GS1 Data Matrix I Low maintenance I Designed for 24/7 production | Robust 7″ LCD Controller I High-speed Date Coder | Print up to 8 lines I Best for PVC pipes and cable printing

Importance of Reliable Cable and Wire Labeling

Reliable cable and wire labeling is crucial for several reasons, ranging from operational efficiency to safety and regulatory compliance. Here are some key reasons why effective labeling is indispensable:

Operational Efficiency

Proper labeling of cables and wires significantly enhances operational efficiency. By clearly identifying cables and wires, technicians can quickly and accurately perform installation, maintenance, and troubleshooting tasks. This reduces downtime and accelerates the resolution of issues, ensuring that production and other operations continue smoothly without unnecessary delays.

Safety and Compliance

Many industries are subject to stringent safety regulations and standards. Reliable labeling ensures that all cables and wires are clearly marked, making it easier to adhere to these regulations. This is particularly important for cables that carry high voltages or those involved in critical systems. Proper labeling helps prevent accidents and ensures that safety protocols are followed.

Enhanced Traceability

In manufacturing and other industries, traceability is a key component of quality control and assurance. Reliable labeling enables traceability of cables and wires, allowing for better inventory management and tracking throughout their lifecycle. This traceability is essential for audits, quality checks, and ensuring that all components meet the required standards.

Ease of Maintenance

Routine maintenance and upgrades are easier to manage with reliable cable and wire labeling. Technicians can quickly identify which cables and wires need to be addressed, reducing the time required for maintenance tasks. This efficiency not only saves time but also reduces labor costs and the potential for human error.

More Coding and Marking Solution

Explore the possibilities of A+++ Industrial inkjet printers…

Date Coder RNJet H1

Doesn’t need any attention, because it just keeps going!

TIJ Printer, Maintenance free

Industrial Inkjet Printer RNJet E1-72+

Serious Performance for Serious Requirements.

Single head, large character

Batch Coder RNJet 100

Incredible Value, Unprecedented Performance!

Single head, more advanced date, batch & lot coding machine