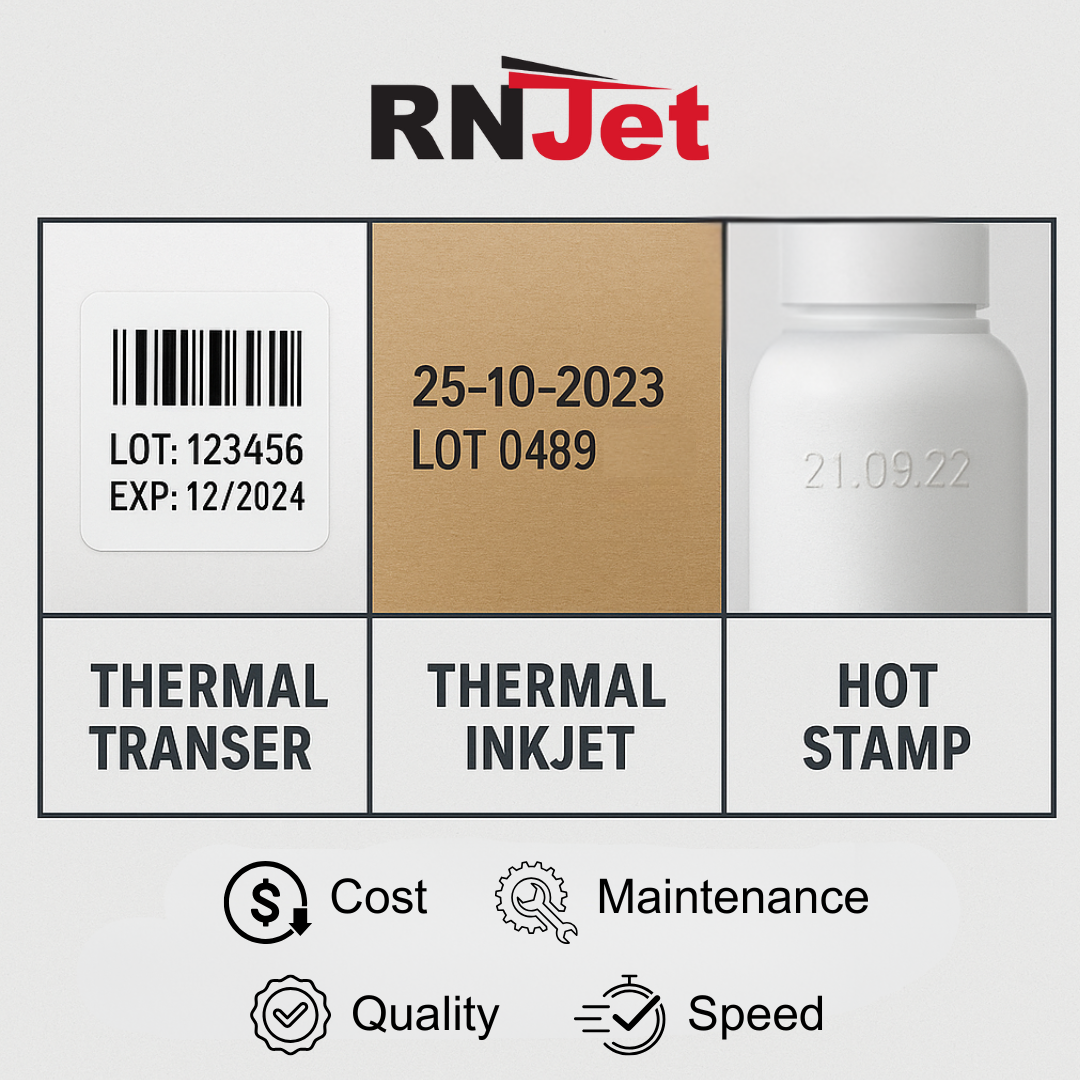

In the world of printing, different technologies cater to various applications and industries. Three popular printing methods—thermal transfer, direct thermal inkjet, and hot stamping—each have unique characteristics that make them suitable for specific purposes. In this blog, we will delve into the differences between these technologies to help you make an informed decision when selecting the right machine for your printing needs.

1. Thermal Transfer Printing

Thermal transfer printing is a versatile technology that utilizes a ribbon to transfer ink onto the substrate. This method is widely used for high-quality and durable printing on labels, tags, and packaging materials.

Key features of thermal transfer printing include:

a. Durability: Thermal transfer printing produces long-lasting prints, making it ideal for applications that require resistance to environmental factors like heat, moisture, and chemicals.

b. Versatility: This method supports a wide range of materials, including paper, polyester, polypropylene, and more. It can handle various colors and offers the flexibility to print variable data.

c. High Resolution: Thermal transfer printing provides high-resolution prints, ensuring crisp and clear images, barcodes, and text.

While thermal transfer printing has many advantages, it also comes with some disadvantages. It’s essential to consider these drawbacks when deciding whether thermal transfer technology is the right choice for a specific application.

Disadvantages associated with thermal transfer printing:

- Cost of Consumables:

- Ribbon Expenses: Thermal transfer printers require ribbons, and the cost of these ribbons can add up over time, especially for high-volume printing. This additional expense should be factored into the overall cost of ownership.

- Complexity of Setup and Maintenance Requirements:

- Thermal transfer printers can be more complex to set up and calibrate compared to direct thermal printers. Achieving optimal print quality may require fine-tuning and adjustments. The printheads in thermal transfer printers may require regular maintenance to ensure consistent print quality. Printhead replacement or cleaning may be necessary, and this can add to the overall cost and downtime.

- Limited Print Speed:

- In general, thermal transfer printing is slower than direct thermal inkjet printing. For applications that require high-speed printing, other technologies might be more suitable.

- Size and Portability:

- Some thermal transfer printers can be relatively large and bulky, which may be a consideration for those with limited space or for portable applications.

Despite these disadvantages, it’s important to note that thermal transfer printing remains a popular and effective choice for various applications, particularly when the durability and longevity of prints are crucial. The decision to use thermal transfer technology should be based on a careful assessment of the specific printing requirements and the advantages and disadvantages of the technology in relation to those needs.

2. Direct Thermal Printing

Inkjet printing involves propelling droplets of ink onto different substrates to create images or text. The print head contains tiny nozzles that release ink in a controlled manner.

Key features of direct thermal printing include:

a. Cost-Effectiveness: Direct thermal printing eliminates the need for ink ribbons, reducing overall consumable costs. It is an economical choice for applications that do not require long-lasting prints.

b. Speed: Direct thermal printers are known for their fast printing speed, making them suitable for high-volume printing environments.

c. High Quality: TIJ technology can produce high-quality prints with sharp text and vibrant colors.

Potential drawbacks associated with Direct Thermal Inkjet printing:

- Drop Placement Accuracy:

- The accuracy of drop placement decreases with an increase in distance. If the printhead is positioned too far from the printing surface, it might result in less precise drop placement, impacting print quality. Suitable for applications where the print head could be placed close to the substrate.

- Alcohol Resistance:

- Prints from traditional inkjet printers are highly sensitive to alcohol. While there are some exclusions, standard inkjet prints may not be suitable for applications requiring alcohol-resistant tests.

- Media and Substrate:

- The durability of TIJ prints is influenced by the characteristics of the printing substrate. Different types of paper, labels, or materials may react differently to the ink. For long-lasting prints, it’s essential to choose media that is compatible with the ink and resistant to factors like moisture and UV exposure.

3. Hot Stamping

Hot stamping is a distinct printing method that uses heat and pressure to transfer a foil or pre-dried ink onto a substrate. This process is often chosen for its ability to create luxurious and eye-catching prints on various materials.

Key features of hot stamping include:

a. Aesthetic Appeal: Hot stamping produces visually appealing prints with metallic or colored foil, making it popular for applications like product packaging, labels, and promotional materials.

b. Embossing: Hot stamping allows for embossing, adding a tactile and premium feel to the printed surface.

c. Limited Color Options: Hot stamping is generally limited to a single color at a time, which may not be suitable for applications requiring multicolor prints.

Potential disadvantages associated with Hot Stamping:

- Limited Color Options:

- Hot stamping is generally limited to a single color at a time. If your application requires multi-color prints or intricate color details, other printing methods like offset or digital printing might be more suitable.

- Setup Costs:

- The initial setup costs for hot stamping can be relatively high. Custom dies or plates need to be created for each design, which adds to the overall expense. This can make hot stamping less cost-effective for small production runs or frequent design changes.

- Material Limitations and Heat Sensitivity of Substrates:

- Hot stamping is most effective on smooth, flat surfaces. It may not adhere well to irregular or textured surfaces, limiting its versatility compared to other printing methods. Some materials may be sensitive to the heat involved in the hot stamping process. This can be a concern when working with heat-sensitive substrates or when trying to avoid potential damage to the material.

Conclusion: What is the Right Printing Technology

Choosing the right printing technology—thermal transfer, direct thermal inkjet, or hot stamping—depends on your specific printing requirements. Consider factors such as durability, cost, speed, and aesthetic appeal when making your decision. Each technology has its strengths, and understanding these differences will help you select the most suitable printing solution for your business or personal needs.

Comments are closed